Low backlash, ultra-quiet, high wear resistance

Worm Gear

Definition of worm gear

Everyone has doubts about what worm gear is. A worm gear is a gear consisting of a shaft with a helical thread, which meshes with and drives the gear. A worm gear is an old-fashioned gear, a version of one of six simple machines. A worm gear is a screw that interfaces with a screw that looks like standard spur gear, with slightly angled and curved teeth.

It changes the rotational motion by 90 degrees, and the plane of motion also changes due to the position of the worm on the worm wheel (or “wheel” for short). They usually consist of steel worms and brass wheels.

Special worm gear for pipe cutting machine

Product name: special worm gear for pipe-cutting machine

Category: Worm Gear

Product introduction: A full range of worm gears in the pipe cutting machine industry

Worm gear for automotive EPS

Product name: Worm gear for automotive EPS

Category: High Precision Worm Gear

Product introduction: ZC1 tooth shape, self-locking

ZC1 series 6-head worm gear

Product name: ZC1 series 6-head worm gear

Category: High Precision Worm Gear

Product introduction:

1. High precision, good rigidity, using special worm gear copper alloy, wear resistance, high strength

2. Dedicated, low inertia coupling for servo motor

Features of worm gears

1. A large transmission ratio can be obtained, which is more compact than the staggered shaft helical gear mechanism.

2. The meshing tooth surfaces of the two wheels are in line contact, and its bearing capacity is much higher than that of the staggered shaft helical gear mechanism. 3. The worm drive is equivalent to the screw drive, which is a multi-tooth meshing drive, so the drive is stable and the noise is small.

4. It is self-locking. When the lead angle of the worm is less than the equivalent friction angle between the meshing gear teeth, the mechanism has self-locking properties and can achieve reverse self-locking, that is, only the worm can drive the worm gear, but the worm cannot be driven by the worm gear. For example, the self-locking worm mechanism used in hoisting machinery, its reverse self-locking can play a role in safety protection.

How a worm gear is made

Worm gears are the most compact type of drivetrain. They are able to fit in very small spaces and still provide a high rate of reduction. With proper installation and installation, the worm gear system runs smoothly and quietly.

The typical way to make a worm gear is to use a hob or cutter for hobbing; this cutting tool is similar to the gears that the worm gear will mate with. Worms can be turned, hobbed, milled or ground.

Worm Gear Lubrication

Proper lubrication is essential for worm gear sets. When turning, the worm pushes the load applied to the worm gear. This results in sliding friction compared to spur gears which mainly generate rolling friction. The best way to minimize friction and metal-to-metal wear between the worm and worm gear is to use a viscous, high-temperature compound gear lubricant (ISO 400 to 1000) with additives. While they can extend the life and improve performance, no lubricant additive can indefinitely prevent or overcome sliding wear.

Rolling friction on a typical gear tooth requires little or no lubricating film to fill the space and separate the two components. Since slip occurs on either side of the tooth apex, a slightly higher lubricant viscosity than strictly required for rolling wear is required to overcome this load. Sliding occurs at a relatively low speed.

Primary worm gear application

One of the most common uses of worm gears is in conveyor belts. Typical worm gears or worm drives can only turn in one direction, making them ideal for conveyor belts that need to be stationary when closed. This locking mechanism allows the worm gear also to be used for safety gates. Usually, security doors have two worm drives, one to open the door and the other to close the door. Worm gear for this purpose means that the safety gate can be locked.

Worm gear drives can be used in apartment and multi-story office buildings, especially elevators or lifts. Also, the irreversible nature of worm gears makes them valuable for elevator mechanics. Although they have an operational function, the elevator’s worm gear also acts as a fail-safe auxiliary braking system, preventing the elevator from free-falling down the hoistway (if the main braking mechanism fails).

Ingenious research and development, casting Seiko quality

Introduction to the working principle of worm gear drive

Sometimes I write About Writing

China Standard DPB full auto red worm blister packing machine shea butter plastic pvc blister packaging olive oil machine price double output worm gearbox

Type: Blister Packaging MachineApplicable Industries: Food & Beverage Factory, Hotels, Manufacturing Plant, pharmaceuticalShowroom Location: Colombia, Egypt, France, Indonesia, Italy, Morocco, Pakistan, Philippines, Russia, Saudi Arabia, South Africa, Spain,...

China Custom Custom Built Gearboxes with Great quality

Applicable Industries: Manufacturing Plant, Machinery Repair Shops, Construction works , Energy & Mining, MACHINERY MANUFACTURERS, CRANEWeight (KG): 1 NMInput Speed: UPTO 2 NMInput SpeedUPTO 2 CJ5E6C525AE 5234910 CJ5E6C525AD 518571 LR033733 Language...

China Custom Cheap Hot Sale High Quality reductor gearbox reduction dc worm gear motor aluminum worm gearbox

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, OtherWeight (KG): 2 KGCustomized support: OEM,...

Why choose us

Concentration Creates Professionalism

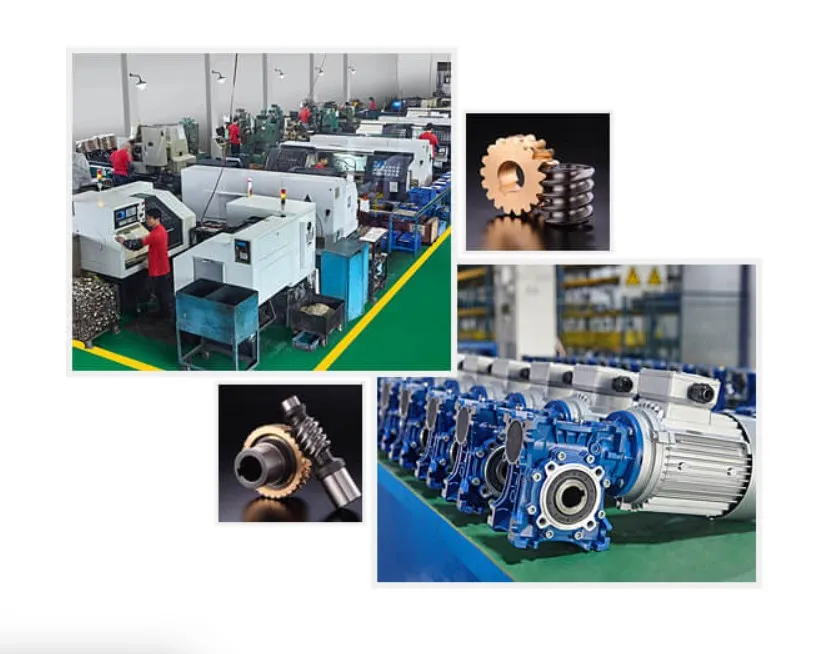

◆Integrating research and development, production, and sales into one, the low-gap servo particular worm gear and worm manufacturing expert.

◆Has many engineers and technicians with more than ten years of industry experience.

◆The company has gear detectors, spectrometers, three-coordinates, and other high-precision testing equipment.

Advanced equipment and sufficient production capacity

Accuracy reaches IT4-IT8 level, quality assurance

◆Strictly implement the ISO9001 quality management system

One-to-one tracking service, worry-free after-sales

Looking for a different product?

If you need a custom product, or the product you need is not found on our website, don’t worry, more of our products are still uploading. You can email us directly and we will reply you within 24 hours!

Email:[email protected]